PT-6 Powerplant Specialists

PT-6 Powerplant Specialists

Rely on dependable and powerful engines

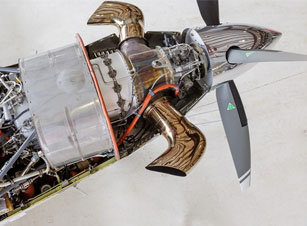

Pratt & Whitney PT6E-66XT

Digital Engine Control

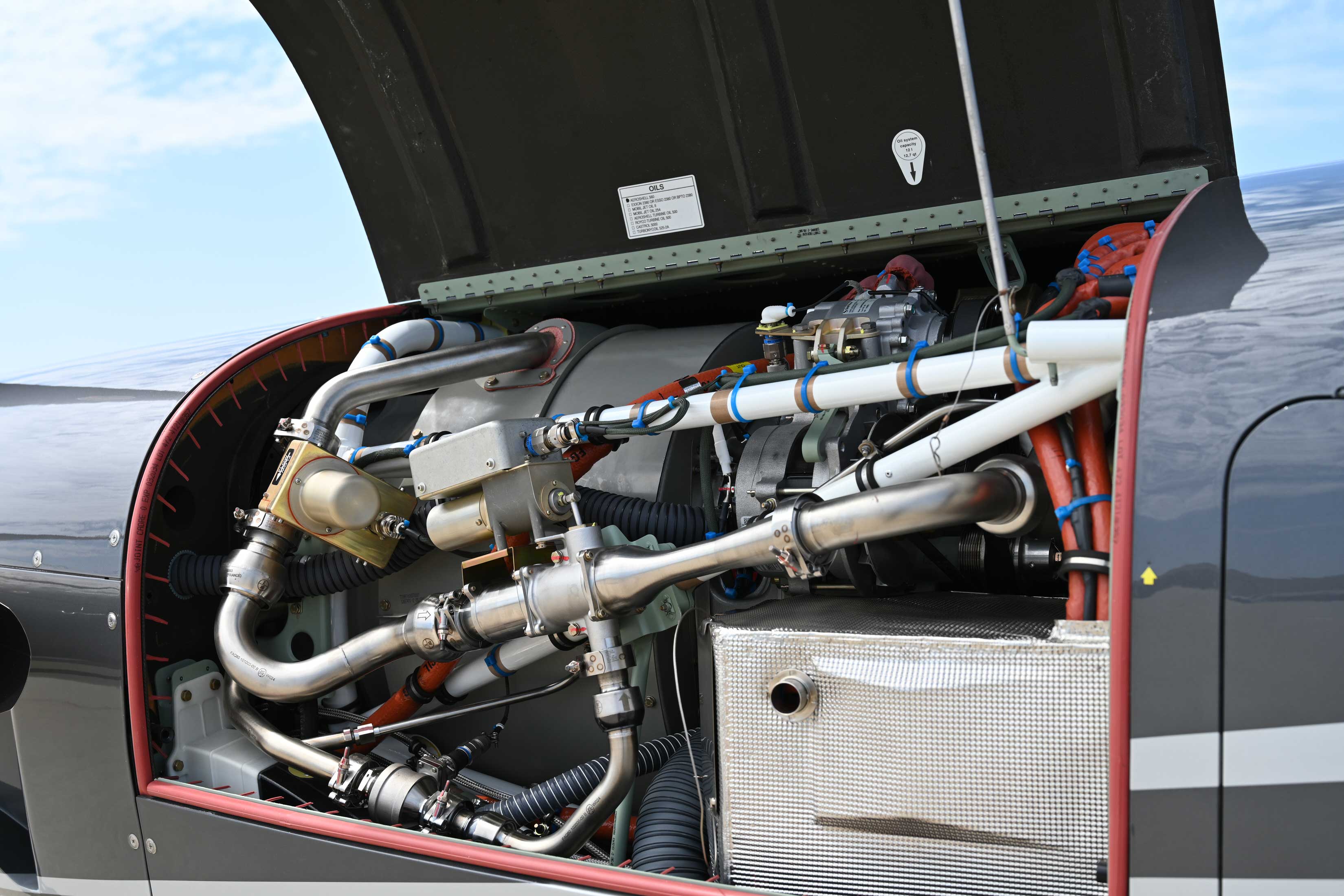

The PT6E-66XT turboprop engine’s simplified single-lever operation offers easy start-up, followed by precise, predictable control and complete digital envelope protection. In addition, it facilitates engine power management and parameter analysis. By combining all engine operations, this minimizes pilot effort while preserving engine life.

Available on the 960.

Pratt & Whitney PT6-66D

The engine that powers the Daher TBM 940 is a Pratt & Whitney Canada PT6A. The simple design of this power plant allows for simple maintenance, high efficiency, and low operating costs, and it is supported by one of the industry’s most extensive support networks. PT6A variants are used on more than 100 different aircraft types. The PT6A is widely regarded as one of the most dependable aircraft powerplants ever created, having more than 43,000 engines in service that have accumulated more than 390 million flying hours.

Available on the 850, 900, 910, 930 & 940.

Pratt & Whitney PT6A-64

Powers the TBM 700A, 700B, 700C2.

Engine Analysis & Evaluation.

Engine Analysis & Evaluation.

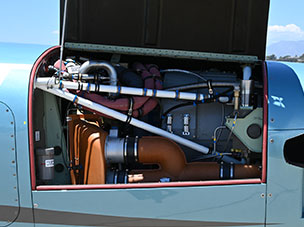

AVEX Aviation Engine Vibration Analysis

AVEX Aviation has harvested over 21 years of data from the PT6 series engines in the TBM and has been able to establish a mean trend line for vibration characteristics of rotating components in the engine. This allows us to take any individual engine and compare it to the normal signature of expected vibration, and quickly spot any anomalies on a rotating component. Using these independent sources, AVEX is able to remove any bias from the analysis and rely on data accumulated over hundreds of thousands of flying hours to make accurate determinations with respect to engine health.

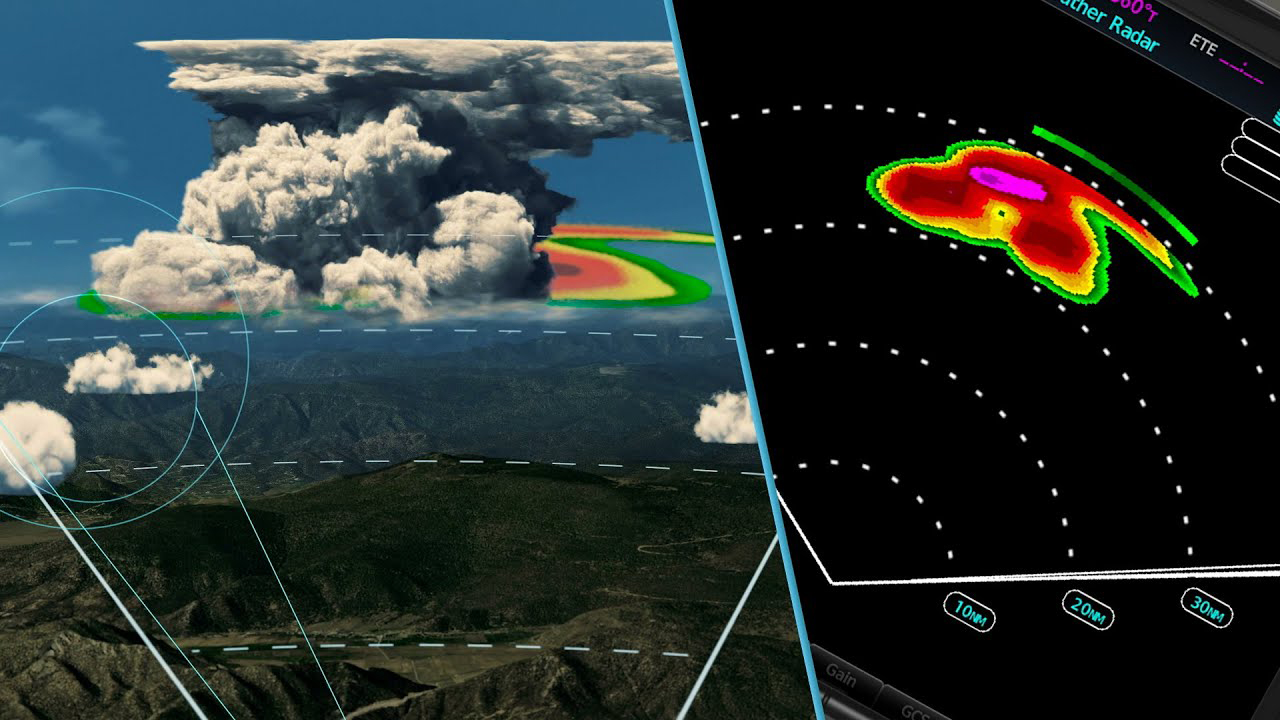

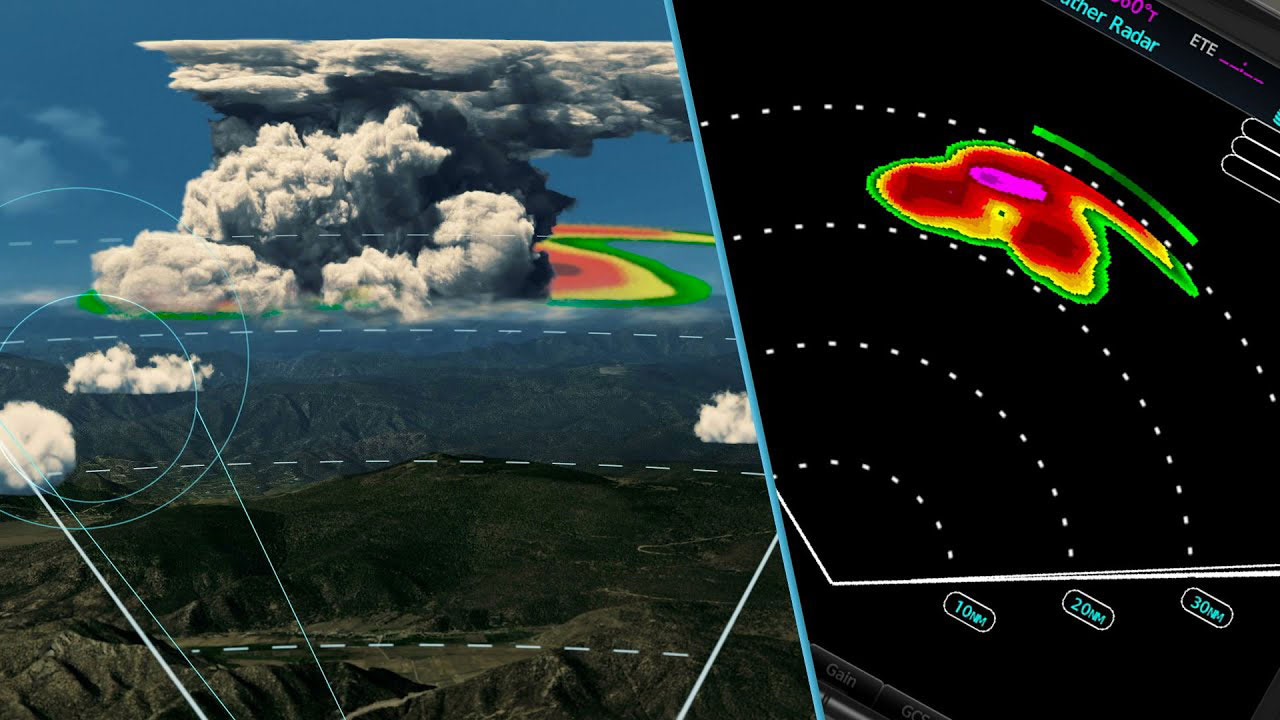

Engine Performance Evaluation

The engine performance is evaluated at each inspection, checking the health of the compressor and turbine sections of the engine. All engine parameters are checked, and performance margins are recorded in our proprietary database to determine if there are any signs of deterioration both on the ground and at altitude. This unbiased approach leverages technology for early detection of anomalies and informed troubleshooting measures reducing further damage and higher maintenance costs.

Pratt & Whitney Oil Analysis Technology

Oil analysis is performed in Pratt & Whitney’s oil laboratory where PWC engineers interpret the results. These results are examined for wear metal impurities suspended in the oil and depending on the concentration and particle size in the sample can be used to indicate areas of distress on the internal rotating components in the engine and used to corroborate vibration anomalies. This is a very valuable service from a safety standpoint and is useful in determining the proper time for the extraction of the engine from the aircraft prior to incurring significant repair costs.

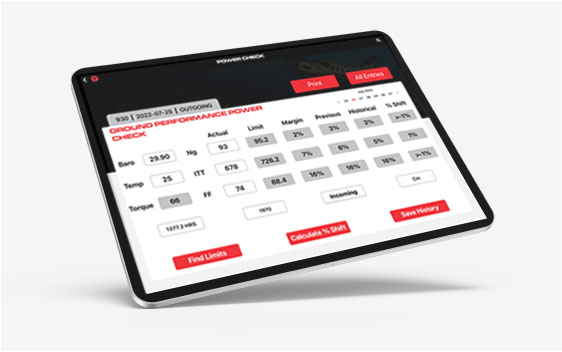

Automated Ground Run Analysis

The AVEX ground performance analysis is critical for evaluating engine condition changes. Once the technician enters the Barometric Pressure and OAT values, our proprietary app correlates the data and determines engine limits. During ground runs, the observed performance data is entered into the program and engine parameter margins are recorded. In order to evaluate engine condition trends, current data are compared to historical data. This information allows us to measure and compare the performance of all TBM models we maintain, from ground operations to cruise altitudes.

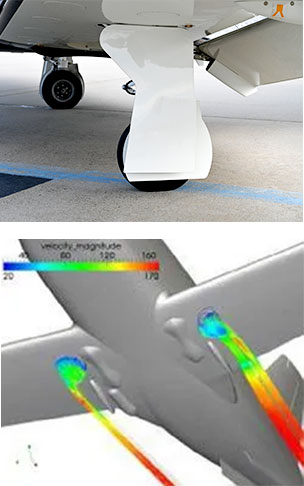

Quieter Cabin

Quieter Cabin

The Hartzell five-blade propeller is substantially quieter in the cabin and pattern.